Freight commercial elevators are essential for efficiently transporting goods in warehouses, distribution centers, and other industrial settings. They are ideal when heavy lifting capacity and high volume are required to move materials from floor to floor.

To ensure smooth operations and maximize the lifespan of your freight elevator, proper maintenance is crucial.

In this article, we will explore key maintenance practices and strategies. These can help you keep your freight elevator running longer.

Regular Maintenance Inspections

Performing regular maintenance inspections is essential for identifying potential issues. Addressing them before they turn into major problems is necessary.

Establish a routine inspection schedule. Also, enlist the services of qualified elevator technicians to conduct thorough examinations.

These inspections should cover critical components such as:

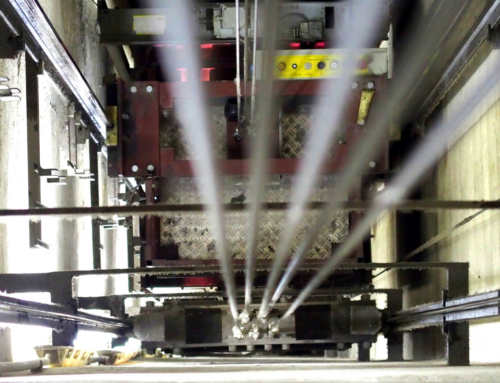

- Hoist system

- Safety features

- Electrical systems

- Control panels

Lubrication and Cleaning

Proper lubrication of elevator components is vital to ensure smooth and efficient operation. Follow the manufacturer’s guidelines for lubrication frequency and use the recommended lubricants.

Regularly clean the elevator components, including the cab, doors, and buttons. This prevents a buildup of dirt and debris that can affect performance.

Keep a Maintenance Log

Maintaining a detailed maintenance log can help you track the history of your elevator’s maintenance activities. Document the following performed on the elevator:

- Inspections

- Repairs

- Servicing

This log will serve as a valuable reference for future maintenance. They can also assist technicians in identifying recurring issues or patterns.

Train Staff on Proper Usage

Proper usage of the freight commercial elevator by staff is crucial for its longevity. Train employees on how to safely operate the elevator, including:

- Loading and unloading procedures

- Weight limits

- Any specific guidelines provided by the manufacturer

Educate staff on how to report any unusual sounds, malfunctions, or safety concerns promptly. Set up incentives for your staff to use the freight elevator accurately.

Stay Updated with Code Compliance

Freight commercial elevators must comply with relevant safety codes and regulations. Stay updated with the latest code requirements.

Regularly review and update safety signage and labels. This ensures compliance with industry standards.

Plan for Modernization

As your commercial freight elevator ages, it may require upgrades to improve efficiency and safety. This is even more true if you are in an older building.

Make sure to work with elevator professionals. They will assess the condition of your elevator. Develop a modernization plan that aligns with your budget.

Facility Owners: Freight Elevator Maintenance Is Key

Freight elevators can have a long life if you take good care of them. Unfortunately, most commercial property owners don’t pay attention to them until it’s too late.

If you are searching for a commercial elevator services company, then we are ready to help. This way, you don’t have to take care of the maintenance of a freight elevator on your own. We will do it all for you.

Contact us today to set up an appointment or to learn more about elevator services.