Did you know as much as 80 percent of machine failures can be traced back to oil contamination?

As most commercial repairers know, monitoring oil in any machine is vital. The oil monitoring process ensures failure rates remain low and saves property managers and repair professionals money and time.

While hydraulic elevators are favored for low maintenance, they use elevator hydraulic oil. If that fails, so does the elevator. And the consequences of a failed elevator can be catastrophic.

Read on to learn some of the benefits of this best practice.

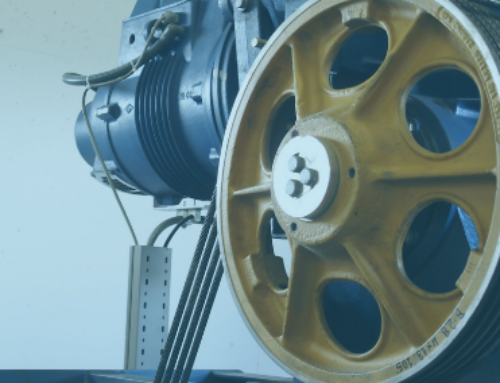

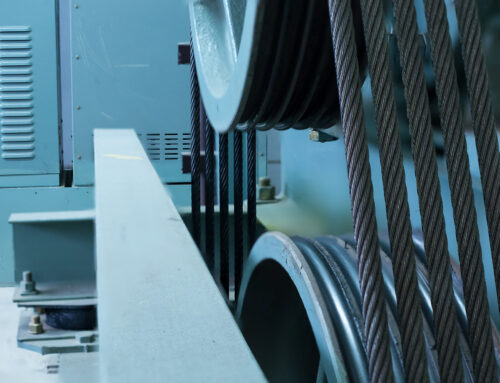

Elevator Hydraulic Oil Is Essential for Operation

When it comes to hydraulic elevator upkeep, the oil is a vital mechanism in the smooth running of the elevator system. The oil acts as a lubricant, reducing friction and ensuring optimal power (or energy) transfer between the cylinder and the pump.

Without oil, an elevator simply won’t get off the ground!

Oil Contamination Causes Failure

Contamination (coupled with oxidization) are the two main reasons why elevator oil needs changing.

Oil can be contaminated with dirt and debris, water, and other foreign particles, altering its natural viscosity and reducing the volume of essential additives. This, in turn, causes parts to wear out prematurely, resulting in poor overall performance.

As a result, oil testing should be a part of any good commercial elevator maintenance schedule.

Oil Testing Is Easy

Thankfully, oil testing is one of the most manageable parts of elevator maintenance, as is knowing when the oil needs testing.

Bad oil causes:

- Stalls and hard stops

- A bad smell

- Leaking fittings and gaskets

- Leveling issues

Sometimes, a maintenance professional might just change the oil, filter it, or flush the hydraulic system. Other times, they may send the oil away for testing. This helps with troubleshooting ongoing issues.

The laboratory tests water levels, oxidation, foreign particles, and additive degradation.

High-Use Elevators Need Frequent Monitoring

The average lifespan of commercial hydraulic elevator oil is around a decade. But higher traffic elevators (or those used for extended periods) go through oil faster than their lower usage counterparts due to more wear and tear on parts. Operating temperature plays a role in oil lifespan, too.

Commercial managers and owners of high-traffic buildings must communicate with their elevator repair professionals to ensure they stay on top of maintenance. This means keeping a maintenance and repair schedule and regularly checking the oil (and testing if necessary).

Check Your Elevator Hydraulic Oil Often

Contaminated elevator hydraulic oil can lead to failure of an elevator—especially in the case of machinery that sees high usage. If an elevator fails at the wrong time, such as when it’s full of people, this can be a PR nightmare for a company at best or an emergency and safety issue at worst.

If you’re looking for a reliable, experienced elevator repair specialist in North Carolina, South Carolina, or Virginia, consider Southern Elevator. Our highly trained technicians will keep your elevators running at peak performance.

Reach out to our team today to discuss your repair or maintenance needs.